Expert Thermal Imaging Services

by Certified Level 3 – Master Thermographer ~ Precision, Reliability, and Expertise for Your Business ~

Delivering Expert Thermography Services for Solar, Building, and Electrical Inspections Across the UK. As certified Level 3 thermographers, we provide expert thermal imaging services across the UK to optimise performance and prevent costly issues in solar, building, and electrical systems.

Comprehensive Thermal Imaging Services Tailored to Your Needs

Building Thermography UK

- Detect heat loss, insulation failures, and structural issues.

- Ensure energy efficiency and meet regulatory standards.

Electrical Thermal Imaging UK

- Identify overheating circuits and prevent electrical failures.

- Condition monitoring of assets for early fault detection.

Solar Panel Thermal Survey UK

- Maximise solar panel efficiency and system longevity.

- Identify malfunctioning panels or connections quickly.

Why Businesses Across the UK Trust Thermography Services (UK) Ltd

Focusing on efficiency & performance

- Certified Level 3 Thermographers: Expertise you can rely on.

- Affordable Thermography Services in the UK: Transparent pricing and custom quotes.

- Cutting-Edge Technology: Industry-leading equipment for precise imaging.

- Detailed Certified Reporting: Easy-to-understand insights tailored to your business needs.

Proven Results with Industry Leaders Across the UK

Our clients include leading solar energy companies, property developers, and industrial manufacturers. Through our detailed thermal imaging reports, they’ve saved thousands on repairs, enhanced operational efficiency, and met compliance standards.

Thermography Services (UK) Ltd

Why Requesting a Free Quote is the Best First Step

- Customised Solutions for Your Business:

Thermal imaging needs can vary widely depending on the industry, the size of the project, and the specific challenges you’re facing. By discussing your requirements, we can determine the most effective approach to deliver optimal results.

- No Obligation, No Risk:

Requesting a free quote is entirely commitment-free. There’s no pressure to proceed, and you’ll gain valuable insights into how our services can address your challenges without any risk or concern.

- Transparent and Clear Pricing:

We believe in transparency. By understanding your needs in detail, we can provide a quote that’s clear, accurate, and free from hidden fees, ensuring you know exactly what to expect.

- Expert Guidance from Certified Professionals:

Our certified Level 3 thermographers are available to answer any questions you have during the consultation. Whether it’s about the process, the technology we use, or the benefits for your business, we’re here to help.

Client Case Studies and Projects

The application of thermography…

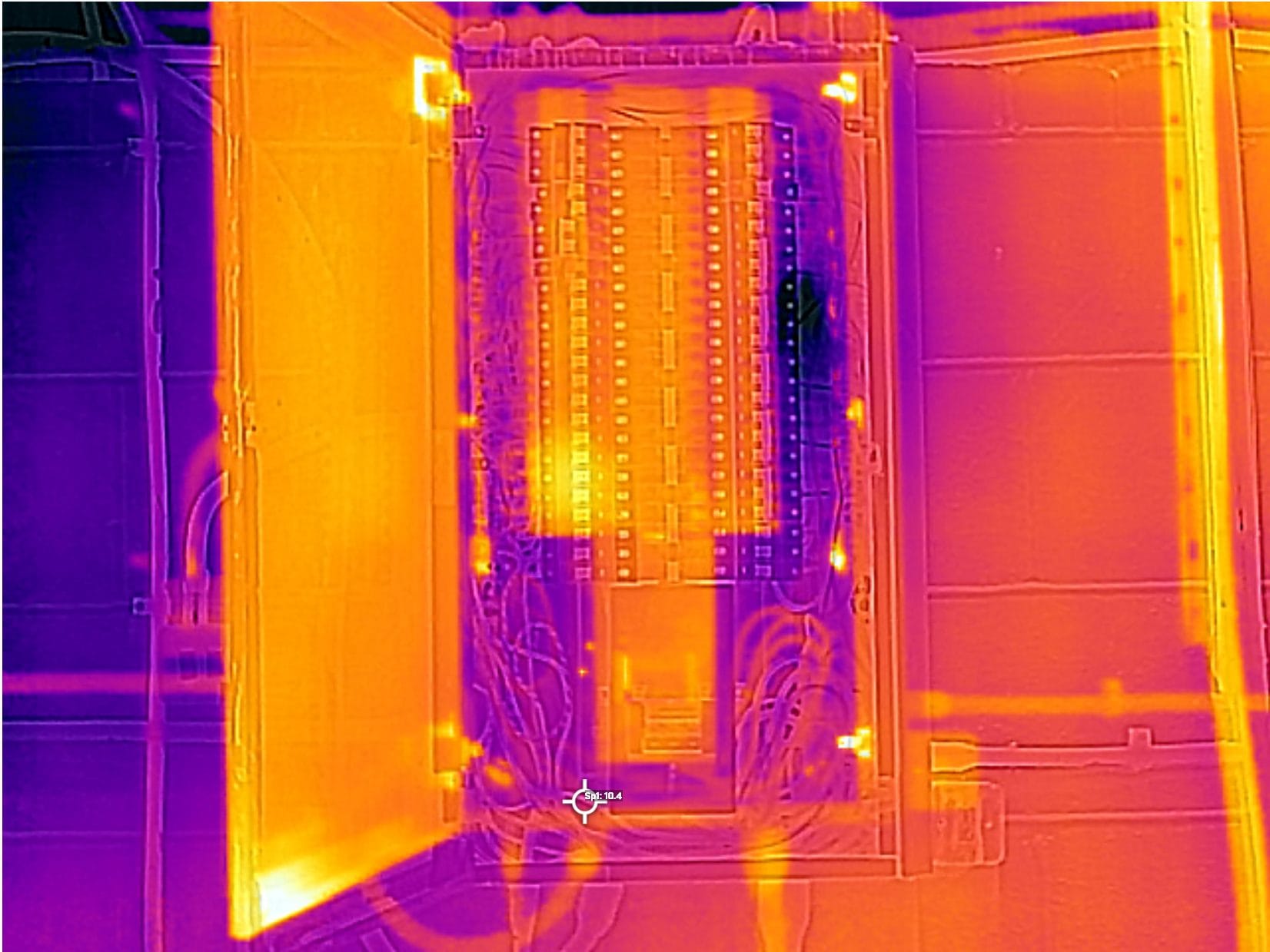

An insurance-led electrical thermography survey was conducted across seven commercial distribution boards to assess fire risk and operational integrity. Using Level 3 supervised infrared inspection aligned with ISO 18436-7 and ISO 9712, the survey identified predominantly stable thermal performance with one advisory-level RCBO observation consistent with load conditions. No critical anomalies were detected. The project demonstrates how structured electrical thermography supports insurer compliance, condition-based maintenance and evidence-led risk management.

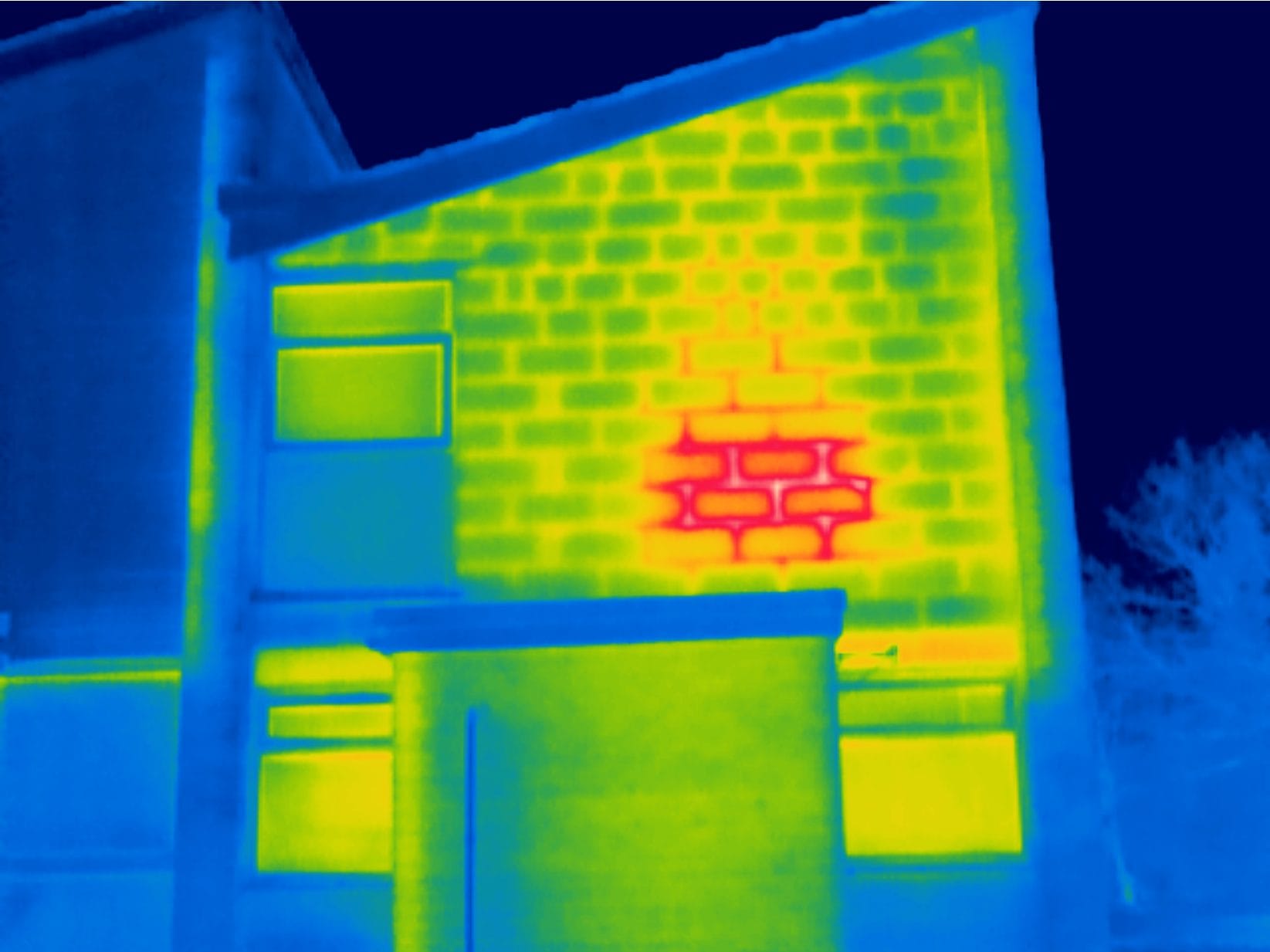

A comprehensive domestic thermography survey identified roof insulation irregularity, variable cavity wall injection performance, slab-to-ground heat loss and structural thermal bridging within a traditional cavity masonry home. While the central heating system was operating effectively, cumulative fabric-level inefficiencies were contributing to reduced heat retention. This project demonstrates how Level 3 thermographic interpretation can diagnose building heat loss scientifically, non-intrusively and in accordance with recognised professional standards.

Image: External dusk thermogram showing a distinct warm brick pattern aligned with an internal radiator position. The geometry suggests conductive heat transfer through masonry where cavity insulation may be reduced or missing, contrasting with cooler surrounding areas that indicate variable insulation performance.

A Level 3 domestic thermography survey of a mid-century bungalow with modern extension revealed consistent loft insulation discontinuity, cumulative window thermal bridging, and junction-level heat loss. Internal and external infrared imaging under controlled winter conditions provided evidence-based insight to support architectural redesign and targeted refurbishment. The inspection identified moderate but widespread inefficiencies, offering a structured foundation for improving thermal performance, comfort, and long-term energy efficiency without intrusive investigation.

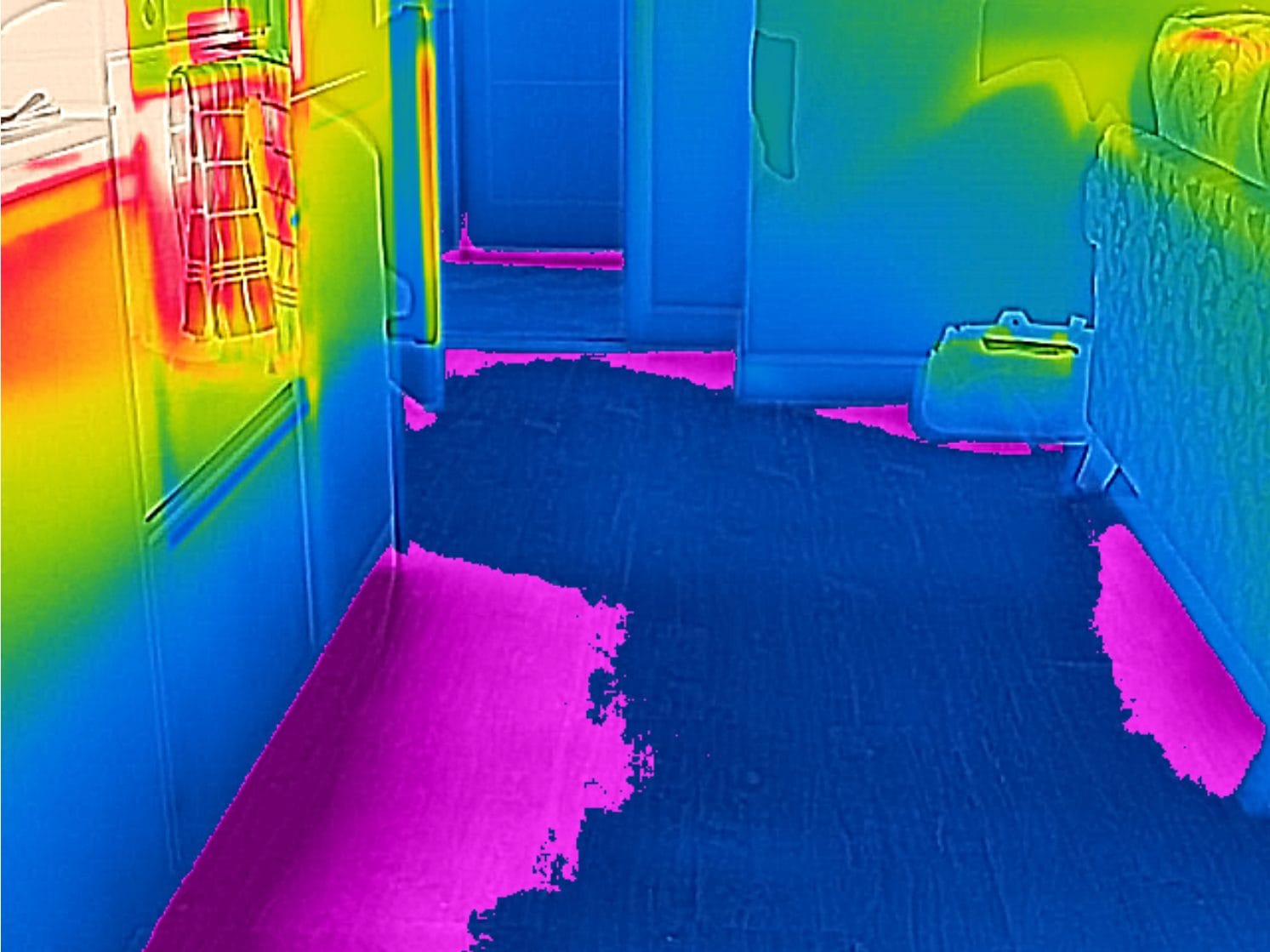

This thermographic case study investigates heat loss in a first-floor apartment adjacent to unheated communal spaces such as riser cupboards, a lift shaft, and an open car park. Using fixed-scale thermal imaging and environmental logging, the survey identified consistent thermal gradients leading from the apartment into colder building core areas. The findings suggest these structural elements may act as passive heat sinks, drawing warmth from the internal space and contributing to the occupant’s persistent comfort issues, despite an otherwise functional heating system.

Exploring the Science Behind Thermal Imaging and Its Practical Applications

What Is Thermography? A Scientific and Technical Insight

Thermography: Making the Invisible Visible, One Heat Signature at a Time.Empowering Precision and InsightProtecting Your Assets with CertaintyUnlocking Hidden Potential in Every System

Thermography: A Window Into Invisible Realms

Thermography, also referred to as thermal imaging, is a powerful non-invasive diagnostic technology that allows us to see what the naked eye cannot. By leveraging advanced infrared technology, thermography captures the natural heat emissions from objects, creating detailed visual representations of temperature variations across a surface. This technology has become an indispensable tool for diagnosing issues in systems, structures, and materials without the need for intrusive methods. Its ability to detect even the slightest temperature differences makes it ideal for identifying problems that could otherwise go unnoticed.

Applications Across Industries

Thermography is a versatile technology with applications across a wide range of industries. In building diagnostics, it helps identify insulation failures, thermal bridging, and air leaks, enabling property owners to improve energy efficiency and reduce costs. In electrical systems, thermal imaging is used to detect overheating circuits, loose connections, and potential failure points before they lead to costly downtime. Similarly, in solar energy, thermography is essential for identifying underperforming solar panels, ensuring the system operates at peak efficiency. Its non-contact nature makes it safe and effective for inspecting complex or hazardous systems.

How Infrared Technology Works

At its core, thermography relies on the principle that all objects emit infrared radiation as a function of their temperature. Infrared cameras are designed to detect this radiation and translate it into a thermogram – a visual image that uses a gradient of colours to represent different temperatures. Warmer areas typically appear in shades of red, orange, or yellow, while cooler areas are displayed in blue or purple. This visual data provides critical insights into the thermal behaviour of objects and systems, revealing anomalies such as overheating components, energy loss, or moisture intrusion.

The Value of Non-Invasive Diagnostics

What sets thermography apart from other diagnostic methods is its ability to deliver accurate, real-time results without physical disruption. Unlike traditional inspections that may require dismantling equipment or penetrating structures, thermal imaging can assess a system’s condition from a distance. This minimises risk, saves time, and provides immediate feedback for decision-making. Moreover, the data obtained from thermography is both qualitative and quantitative, allowing for detailed analysis and actionable insights. As a result, businesses and industries can proactively address issues, optimise performance, and prevent costly failures with confidence.

The Science Behind Thermography:

Thermography is grounded in the fundamental principle that all objects emit infrared radiation as a natural byproduct of their temperature. This radiation, invisible to the human eye, provides valuable clues about an object’s thermal properties. Infrared cameras are engineered to detect these emissions, translating them into a thermogram—a visual representation of temperature differences across a surface. Thermograms use a colour scale, with warmer areas typically appearing in red, orange, and yellow, and cooler regions in blue and purple. This visualisation enables professionals to analyse heat patterns, identify anomalies, and make informed decisions without direct contact or physical disruption.

Key Scientific Concepts That Enable Thermography

- Infrared Radiation:

Infrared radiation is a form of electromagnetic energy that lies just beyond the visible light spectrum. Unlike visible light, infrared cannot be seen with the naked eye but is emitted by all objects, regardless of their state. The amount of infrared energy an object emits is directly proportional to its temperature. This makes infrared detection a reliable indicator of heat distribution and variations across surfaces. Thermography uses this property to uncover critical insights, whether it’s pinpointing an overheating electrical connection or identifying energy loss in a building. - Emissivity:

Emissivity is a measure of how efficiently an object emits infrared radiation relative to a perfect blackbody, which is a theoretical object that absorbs and emits all radiation perfectly. Different materials have different emissivity values, which play a crucial role in the accuracy of temperature measurements. For example:- High-Emissivity Materials: Surfaces like matte black paint or oxidised metals emit infrared radiation efficiently and provide accurate temperature readings.

- Low-Emissivity Materials: Polished metals or reflective surfaces, by contrast, tend to reflect ambient radiation, which can lead to inaccurate measurements if not properly accounted for.

Understanding and adjusting for emissivity ensures precise readings, particularly in complex environments.

- Heat Transfer Mechanisms:

Thermography is invaluable in identifying anomalies in heat transfer caused by one or more of the following mechanisms:- Conduction: Heat transferred directly through a material. For instance, thermography can reveal poor insulation in a building where heat is escaping through walls or roofs.

- Convection: The movement of heat through fluids like air or water. This is critical in detecting air leaks or inefficient HVAC systems.

- Radiation: The emission of heat energy as infrared radiation. Anomalies in radiative heat transfer are often seen in electrical systems where overheating components radiate more heat than usual.

By distinguishing between these mechanisms, thermography provides detailed insights into the source of inefficiencies or failures.

Technical Factors in Thermal Imaging:

Thermography is not only a sophisticated diagnostic technique but also a discipline that demands technical precision and an understanding of its operational complexities. While the principle of detecting infrared radiation might seem straightforward, the practical application involves a myriad of factors that influence the accuracy and reliability of the results.

From the capabilities of the thermal imaging equipment to the expertise of the operator, every detail matters when interpreting heat patterns and identifying anomalies. For businesses and industries relying on thermography, understanding these technical factors ensures that inspections are not only thorough but also actionable.

The performance of thermographic equipment is shaped by both the technology behind the cameras and the environmental conditions in which they are used. High-quality thermal cameras equipped with advanced features like high resolution, exceptional sensitivity, and accurate calibration provide the foundation for precise thermal imaging.

However, these tools alone are not enough; skilled thermographers must account for variables such as material emissivity, background radiation, and changing weather conditions to produce meaningful and dependable results. By addressing these considerations, thermography achieves its full potential as a critical tool for preventive maintenance, energy efficiency, and fault detection.

Technical Factors in Thermal Imaging:

Additional Technical Factors to Consider

- Thermal Resolution and Sensitivity:

The ability of a thermal camera to detect subtle temperature differences is determined by its thermal resolution and sensitivity. High-resolution cameras are essential for detailed inspections, allowing professionals to spot even minor irregularities in complex systems. Sensitivity, measured in millikelvins (mK), determines how finely a camera can distinguish temperature variations, which is crucial for early detection of issues. - Temperature Calibration:

Infrared cameras must be regularly calibrated to ensure their readings are accurate and reliable. Calibration aligns the camera’s sensors with known temperature standards, accounting for factors like ambient conditions and sensor drift over time. Without proper calibration, readings can become inconsistent, reducing the diagnostic value of thermography. - Environmental Impact on Measurements:

External factors such as wind, humidity, and sunlight can affect the accuracy of thermographic readings. For instance, reflective surfaces exposed to direct sunlight might give false readings, while wind can cool surfaces and obscure true heat patterns. Skilled thermographers adjust for these variables during inspections, ensuring accurate results.