Why November is Prime Time for Home Heating Thermography

Why November is the Prime Time for a Home Heating Survey Using Thermography

Don’t wait for the frosts – discover hidden heating losses and optimise your system before winter fully bites.

As the colder months set in, now is the perfect moment to commission a residential heating survey using advanced thermography. Our Level 3 Master Thermographer will identify heat losses, inefficient flow, poor insulation and uneven heating patterns – giving you clarity and actionable insights ahead of peak demand and high energy bills.

Why November is the Ideal Time for Your Home Heating Survey

The seasonal context

When outdoor temperatures begin dropping and regular heating starts, the building and its heating system shift from idle or intermittent use into sustained operation. This is the moment when hidden inefficiencies start to reveal themselves: fabric heat-loss paths, inadequate insulation, unbalanced radiator flow and under-performing pipework all become more visible. December and beyond bring peak loads and less opportunity to defer corrective work, so taking action in November gives you the window.

Thermography: a powerful diagnostic tool

Using an infrared-camera survey, we can visualise surface temperature differences across walls, ceilings, floors, radiators and pipework – identifying anomalies that wouldn’t show up in a visual inspection alone. As noted by Historic England: “Infrared thermography is a non-destructive means of investigation by capturing the heat energy emitted from the surface of a material.” Historic England

From our perspective, our Level 3 Master Thermographer qualification brings advanced interpretation, ensuring you receive reliable, compliance-ready reporting rather than just imagery.

What We Inspect in a Heating Survey

Key areas of focus

Why our Level 3 thermography matters

Benefits of Acting Now (November)

November offers the ideal environmental window for a heating performance thermography survey. External temperatures have dropped enough to create a meaningful temperature differential (ΔT) between the inside and outside — typically the 10 °C – 15 °C difference required under EN 13187:1999 for accurate building heat-loss analysis. This differential allows our thermal imaging equipment to detect subtle variations in surface temperature across walls, floors, and ceilings that would otherwise be invisible in warmer months.

Another advantage of surveying in November is that heating systems are now operating under realistic seasonal conditions, but not yet at their most demanding. This allows inefficiencies to be captured before they turn into reliability problems. Issues such as unbalanced radiators, air locks, degraded insulation, or under-performing controls become immediately apparent when viewed through a calibrated infrared camera.

A proactive survey before mid-winter also provides time for cost-effective remedial action. Small maintenance steps — like sealing insulation gaps, balancing circuits, or adding pipe lagging — can prevent major discomfort and expense later in the season. Early identification ensures work can be scheduled ahead of the year-end rush, avoiding emergency call-outs during the coldest months.

From a financial standpoint, thermography-guided maintenance is one of the most cost-efficient investments you can make. Even modest heat-loss corrections can deliver measurable returns through reduced gas or electricity consumption. With energy prices remaining unpredictable, now is the time to assess and improve the efficiency of your home’s thermal envelope and heating system.

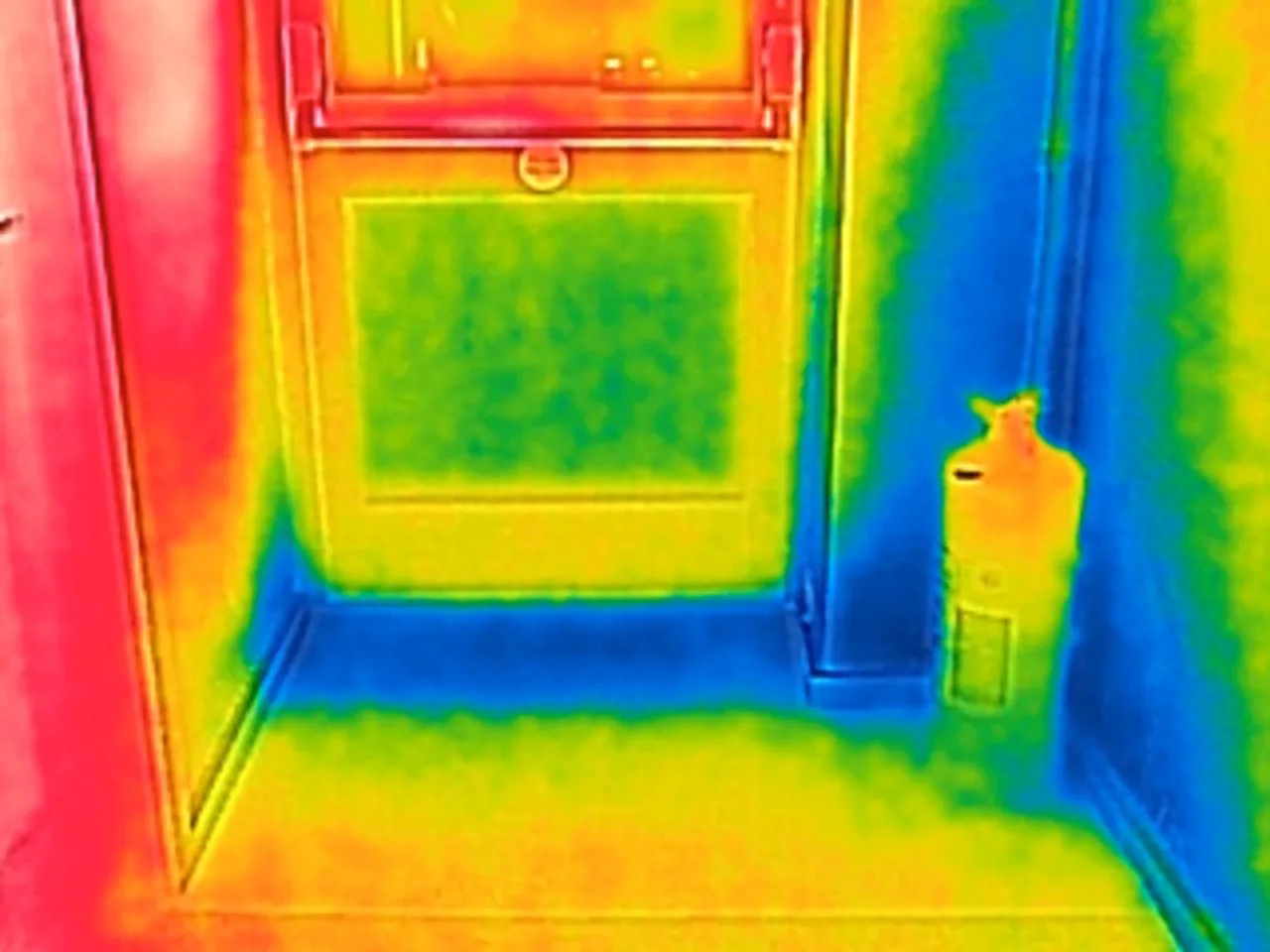

Case Study: Domestic Heating Survey

Client: Semi-detached family home, Sussex

Date: November 2024

Survey Type: Full internal heating performance thermography under ISO 18436-7 Level 3 supervision

A local homeowner contacted us after noticing inconsistent warmth between rooms — the lounge felt noticeably colder than the rest of the house despite identical radiator settings. Using a FLIR T530 thermal camera, the survey revealed multiple issues: the single-storey kitchen extension was losing heat through its flat roof, while an upstairs radiator was only half-heating due to a partially closed lockshield valve.

Radiometric thermograms showed clear cold-spot patterns along the roof joist lines, suggesting missing or poorly fitted insulation. A further scan of the ground-floor heating circuit displayed an excessive temperature drop between flow and return lines, recorded at over 15 °C (typical expectation 10 °C). This indicated insufficient pipe insulation within the subfloor zone.

Following the inspection, we provided a structured report outlining specific corrective measures:

Replace faulty radiator valve to restore balanced flow.

Upgrade insulation in the kitchen roof to achieve uniform U-value performance.

Add pipe lagging along the accessible under-sink and crawl-space circuits.

Within two weeks, the homeowner completed these minor works. A short follow-up thermographic check confirmed even heat distribution and a 40 % reduction in the thermal differential across the ground floor. Over the subsequent winter, gas consumption readings showed an estimated £180 annual saving and improved comfort, validating the cost-effectiveness of early-season thermography.

What to Expect When You Book With Us

Pre-survey briefing – we explain what we’ll do, what you should prepare (e.g., turning on heating system 30 mins before arrival).

On-site survey – using high-resolution radiometric infrared camera, following structured inspection methodology.

Analysis & Reporting – our Level 3 thermographer analyses data, correlates findings, and produces a structured report with images, findings, prioritised recommendations.

Post-survey review – we discuss the report with you, answer questions and align next steps (insulation, radiator works, system servicing).

Follow-up option – optional revisit or verification after works to confirm improvements.

Don’t wait for the cold to expose the problems. Book your home heating thermography survey now and step into winter with confidence

Discover how a Level 3 Master Thermographer can optimise your building’s heating and insulation performance while enhancing its sustainability. Contact us today for a thermographic survey and experience the benefits of using thermography in building maintenance firsthand.

Thermography Services (UK) Ltd

Certified Master Thermographer