~ Summary ~

A professional Level 3 thermographic review was commissioned to analyse the insulation and surface heat-transfer performance of a large refrigerated LPG storage tank. The study focused on identifying potential areas of heat loss, conduction, or insulation variability that could influence operational efficiency or indicate localised deterioration. Using calibrated infrared thermography, the assessment examined the tank’s roof, walls, and base to establish a complete temperature profile and determine whether any features required further inspection. This specialist analysis demonstrates how advanced industrial thermography can support critical infrastructure maintenance and assurance programmes. Through precise emissivity correction, temperature linear scaling, and environmental compensation, the results provided clear insight into how the tank behaves under cryogenic storage conditions. The findings confirmed stable insulation performance with no evidence of significant anomalies, highlighting the value of certified Level 3 thermography for reliable diagnostics in LPG storage and cryogenic process applications.

Delivering technically validated insights through expert infrared data interpretation.

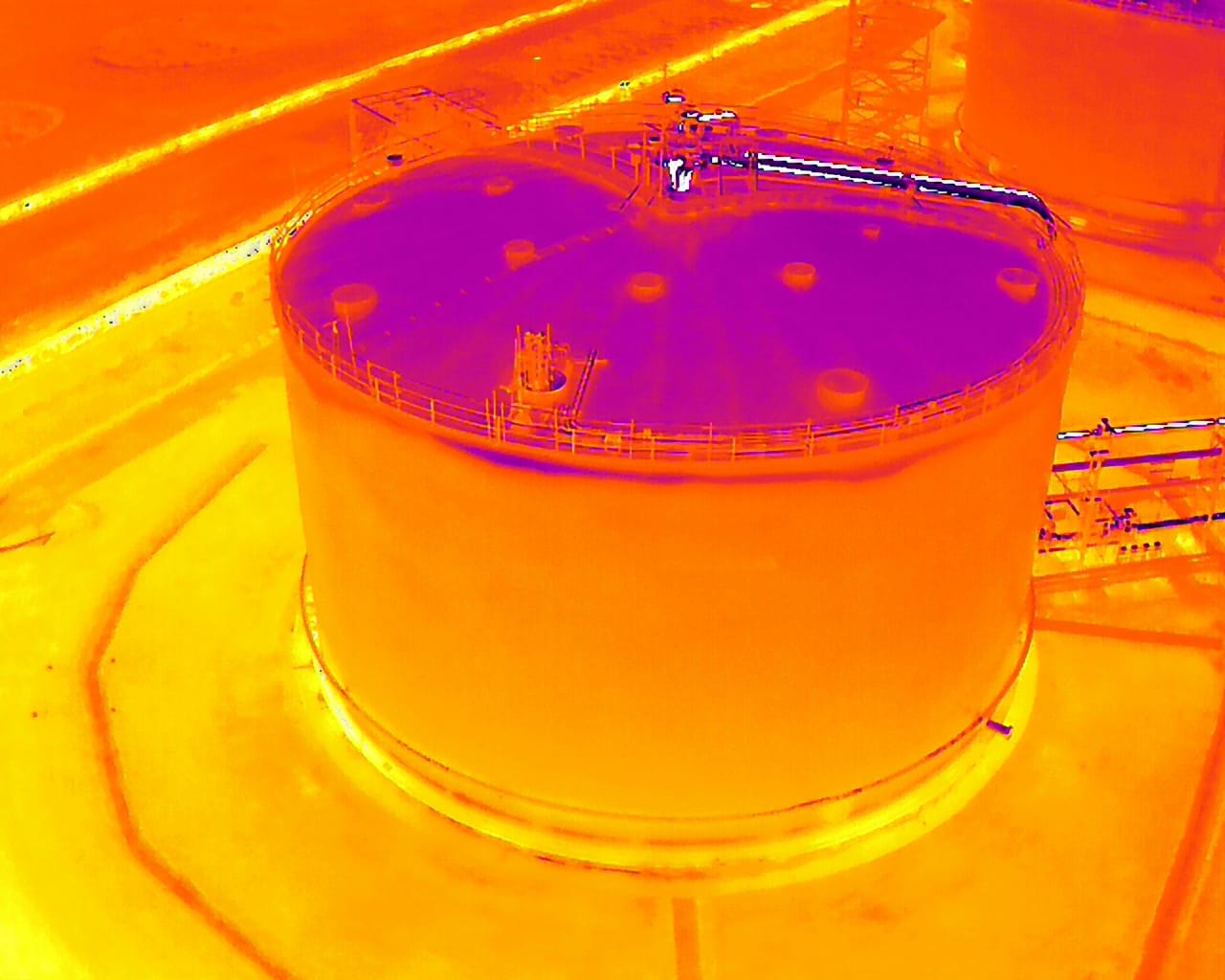

A complex dataset of aerial and ground-level thermograms was provided for expert interpretation following concerns regarding possible leakage from a large refrigerated LPG tank. The survey had been conducted under challenging environmental conditions, and our role was to validate the captured data, assess its diagnostic integrity, and extract reliable thermal evidence through advanced post-processing.

Working within recognised international standards for refrigerated hydrocarbon storage (API 620/650 and BS EN 14620), the thermal images were reviewed using a calibrated, temperature-linear workflow in FLIR Studio Pro. Careful correction for emissivity and environmental variables enabled accurate comparison of surface temperature differentials across the tank’s structure, roof, and base. The analysis distinguished between expected material and environmental influences and potential insulation-related anomalies, maintaining the cautious, evidence-led approach required for this type of critical infrastructure.

The resulting professional report was completed under our Level 3 certification and delivered to the client as a white-label document. It provided technically credible conclusions, identified areas for optional further inspection, and served as a benchmark for best-practice reporting in industrial thermography.

industrial thermography, cryogenic tank inspection, thermal imaging, LPG storage, infrared analysis, insulation testing, Level 3 thermography, heat transfer assessment, refrigerated systems, professional thermography report

Approach and Pre-Project Considerations

The thermographic data was supplied from an aerial drone platform using a radiometric thermal sensor. Our first task was to establish environmental conditions, including a relative humidity of over 80 %, which exceeded ideal thresholds for high-accuracy thermography. Recognising that this factor would slightly reduce contrast, the analysis was nonetheless viable for qualitative review. Using Level 3 evaluation methods, the data was normalised, emissivity assumptions applied, and baseline reference areas selected to ensure accurate comparison between roof, wall, and base regions.

Key Observations and Findings

The overall thermal behaviour of the tank was stable, with wall and roof temperatures closely tracking ambient conditions. No evidence of large-scale insulation failure or active cold leakage was identified. A localised cooler band approximately 3 °C below baseline was observed near the upper wall section; its partial continuity suggested a combination of insulation variability and structural conduction at the roof junction rather than systemic bridging. At ground level, a colder union was identified, consistent with product conduction through uninsulated pipework rather than seal failure.

Outcome & Interpretation

The outcome of this advanced thermographic analysis confirmed that the tank was operating within normal and expected parameters for refrigerated LPG storage. The majority of observed thermal behaviour corresponded to predictable patterns resulting from differences in material conductivity, insulation thickness, and exposure to environmental variables such as sky radiation and ambient air temperature. By referencing multiple thermal datasets and standardising the temperature scale across all thermograms, the analysis ensured consistent interpretation and avoided the risk of false contrast arising from auto-scaled imaging.

Particular attention was paid to the apparent cool band observed near the roof-to-wall junction. Its partial presence and later disappearance across sequential thermograms indicated that it was not a structural or systemic thermal bridge but more likely an environmental or localised insulation effect. This interpretation is supported by the absence of circumferential continuity and by thermal readings from opposing sides of the tank, which displayed uniformity. Similarly, the cooler ground-level union was interpreted as a result of expected thermal conduction from cryogenic product through uninsulated metallic fittings rather than any failure of sealing components.

Overall, the combined analysis of these features demonstrated a stable thermal profile consistent with sound insulation integrity. While thermography cannot verify product containment directly, it can provide clear evidence of external heat flow behaviour. The findings were therefore categorised as normal, with minor local variations falling within expected tolerances. The final report provided the client with reliable technical assurance that no abnormal or critical insulation failure was evident during the period of observation, while also highlighting optional areas for inspection during future scheduled maintenance or independent verification.