Commercial Electrical Distribution Board & Panel Thermography Inspections

Ensuring electrical safety, insurance compliance, and operational reliability through certified thermal imaging inspections.

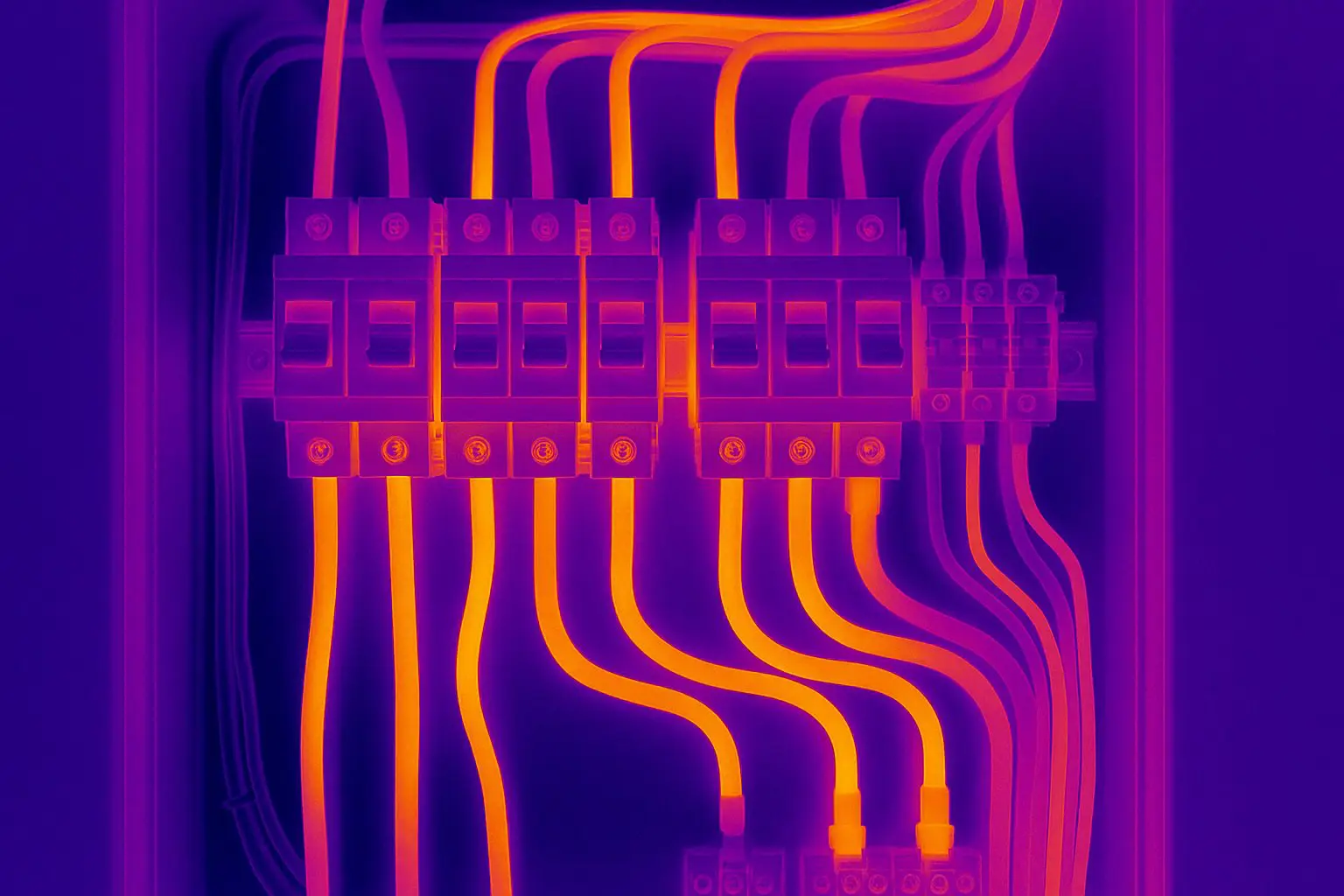

Commercial electrical distribution board inspections using thermography provide a fast, non-intrusive way to identify faults such as overheating connections, phase imbalance, and overloaded circuits. By carrying out live thermal imaging surveys, our Level 3 Certified Thermographers detect problems before they escalate into costly failures or fire hazards. These inspections are essential for ensuring electrical safety, reliability, and compliance in commercial environments.

Many insurers now require annual electrical panel thermography as part of their risk management standards. Our certified thermal imaging reports meet ISO and IEC requirements and are recognised for insurance compliance. By scheduling an annual electrical panel thermal imaging survey, businesses can demonstrate preventative maintenance, reduce liability, and maintain uninterrupted operations with confidence.

Thermographic testing for insurance compliance and annual electrical panel thermal imaging survey

Thermographic surveys of commercial electrical distribution boards go beyond simple fault detection. The process provides businesses with a clear picture of load distribution, operating temperatures, and the overall health of their electrical systems. This valuable insight supports planned maintenance strategies, ensuring resources are targeted where they are most needed rather than relying on reactive repairs.

Certified thermography also plays a critical role in demonstrating compliance with both insurer requirements and recognised technical standards. By following ISO 18434 and IEC 62446-3 methodologies, our reports provide a transparent, evidence-based assessment of electrical safety. Each inspection is carried out by a Level 3 Thermographer, ensuring that results are not only technically accurate but also delivered in a format trusted by insurers and risk assessors.

For many businesses, the real benefit lies in risk reduction and operational continuity. A single electrical fault can result in equipment shutdowns, production delays, or safety hazards for staff. By investing in an annual thermographic inspection, organisations gain peace of mind that their distribution boards and panels are operating within safe parameters, while having the confidence that any issues will be detected and addressed before they become critical.

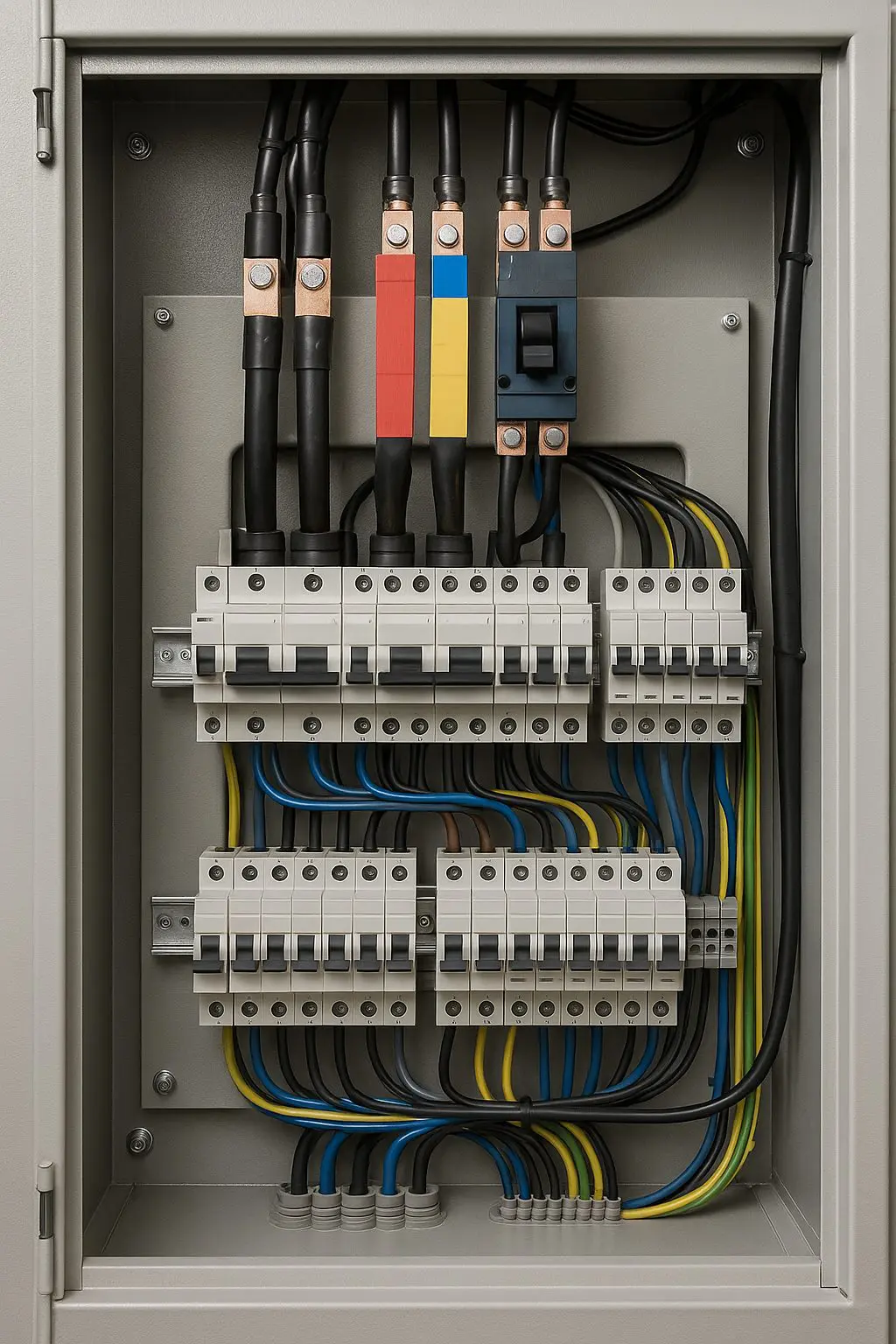

Commercial electrical distribution board inspection

Electrical thermography

Distribution board inspection

Thermal imaging survey

Electrical panel testing

Certified Thermographic Inspections for Commercial Distribution Boards

Electrical distribution boards and panels form the central hub of a building’s electrical infrastructure, directing power safely across circuits and equipment. Any hidden fault within these systems — such as loose terminations, unbalanced phases, or overloaded connections — can quickly escalate into overheating, fire hazards, and costly system failures. Because these issues often develop silently over time, they are rarely visible during routine checks, making thermographic inspection an essential layer of preventative maintenance.

By using advanced thermal imaging technology, our Level 3 Certified Thermographers can conduct non-intrusive live testing of your distribution boards under normal operating conditions. This allows us to identify abnormal temperature rises that indicate potential problems, without the need for shutdowns or invasive testing. Unlike standard electrical checks, thermography provides a real-time visual map of heat distribution across the board, making it possible to pinpoint precise areas of concern and prioritise corrective action before disruption occurs.

Our inspections are carried out in line with international standards, including:

What the Survey Covers

Scope of inspection:

Main distribution boards

As the central hub of an electrical installation, main distribution boards carry the highest current loads and are critical to overall building safety. Thermographic inspections allow us to identify hotspots caused by loose terminations, overloaded connections, or deteriorating components. Early detection ensures continuity of supply, reduces the risk of fire, and provides the evidence insurers require for annual compliance.

Sub-distribution panels

Sub-distribution panels feed specific circuits or building zones, and while they may operate at lower loads than the main board, faults within them can still present significant risks. Thermal imaging highlights imbalanced loads, loose connections, and defective breakers that could otherwise lead to localised outages or safety hazards. Regular inspection ensures resilience across the wider electrical network.

Switchgear and busbars

Switchgear and busbars are high-capacity components designed to safely control and distribute large volumes of electricity. Any abnormal heating within these assemblies can indicate insulation breakdown, contact wear, or overloading. A thermographic survey provides a non-intrusive means of verifying performance under live operating conditions, reducing the chance of catastrophic failure and meeting insurer expectations for preventative maintenance.

Fused isolators and breakers

Fused isolators and protective breakers are designed to safeguard circuits from overload and fault conditions, but they themselves are susceptible to wear, ageing, and loose connections. Thermal imaging can identify overheating fuses or contacts before they fail, helping to avoid costly downtime. Documenting these inspections annually provides both operational assurance and compliance evidence for insurers.

MCC (motor control centres) where applicable

In industrial and process-driven environments, MCCs play a vital role in controlling motors and automation equipment. These systems can be subject to heavy use and variable loads, making them prone to thermal anomalies. Thermography provides a clear assessment of contactors, overload relays, and power connections without interrupting production. Identifying issues early protects critical assets and supports insurer-mandated maintenance schedules.

Annual Insurance Requirement:

Insurance providers increasingly recognise the value of thermographic inspections as part of a comprehensive risk management strategy. In fact, most insurers now stipulate that all electrical distribution boards, switchgear, and panels larger than 0.7 m² must be inspected at least once every year by a qualified thermographer. This requirement reflects the proven ability of thermal imaging to identify risks such as overheating connections, imbalanced loads, or defective components before they result in fire or equipment failure.

Insurance providers increasingly recognise the value of thermographic inspections as part of a comprehensive risk management strategy. In fact, most insurers now stipulate that all electrical distribution boards, switchgear, and panels larger than 0.7 m² must be inspected at least once every year by a qualified thermographer. This requirement reflects the proven ability of thermal imaging to identify risks such as overheating connections, imbalanced loads, or defective components before they result in fire or equipment failure.

Our inspections are specifically designed to satisfy these compliance obligations. Each distribution board is opened by a qualified electrician, imaged under live operating load, and assessed by a Level 3 Certified Thermographer. The resulting report provides clear thermal images, annotated findings, and categorised recommendations, all structured in line with ISO 18434 and IEC 62446-3 standards. This ensures that your business has a credible, independently certified record that insurers accept as evidence of proactive maintenance and risk control.

By undertaking an annual electrical panel thermal imaging survey, businesses not only meet their insurance compliance requirements but also demonstrate a commitment to safety and preventative maintenance. This proactive approach can help to reduce liability, streamline claims processes, and in many cases, support negotiations for reduced insurance premiums.

How the Inspection is Conducted

Thermographic surveys of electrical panels must be conducted live, under normal operating load, for accurate results. For safety and compliance:

A qualified electrician is required to open panels safely.

Our Level 3 Thermographer conducts the thermal imaging, capturing radiometric data of every panel.

Findings are analysed, anomalies categorised (minor to critical), and recommendations provided.

This process ensures compliance with insurance mandates, prevents unplanned downtime, and supports best-practice electrical safety management.

Why Annual Testing Matters

Electrical faults such as loose terminations, phase imbalance, or overloaded circuits develop over time. Annual thermographic testing ensures:

Early detection before faults escalate

Compliance with insurer requirements

Reduced fire risk and equipment failure

Evidence of preventative maintenance in case of audit or claim

Key Benefits of Thermography with a Level 3 Specialist

Thermography conducted by a Level 3 Certified Specialist provides businesses with the highest standard of accuracy, reliability, and compliance. Unlike entry-level surveys, Level 3 inspections ensure that every thermal image is captured, analysed, and reported using industry-recognised methodologies, including ISO 18434 and IEC 62446-3. This level of expertise guarantees that findings are correctly interpreted and that the final report can withstand insurer audits, risk assessments, or regulatory reviews.

For commercial clients, the benefits are both technical and practical. A Level 3 thermographer not only identifies hidden faults in electrical distribution boards and panels but also delivers fully certified documentation trusted by insurers and facility managers. This professional assurance supports compliance with annual insurance requirements, reduces liability, and provides actionable insights that help businesses maintain safe, efficient, and resilient electrical systems.

Choosing a Level 3 Certified Thermographer ensures the highest standard of inspection and reporting. Benefits include:

Insurance compliance, Electrical safety, Non-intrusive testing, Fault detection, Risk reduction, Fire prevention, Energy efficiency, Preventative maintenance, Thermal survey, IEC 62446-3, ISO 18434, Live testing, Distribution boards, Switchgear, Level 3 certified, Electrical reliabilityInsurance compliance, Electrical safety, Non-intrusive testing, Fault detection, Risk reduction, Fire prevention, Energy efficiency, Preventative maintenance, Thermal survey, IEC 62446-3, ISO 18434, Live testing, Distribution boards, Switchgear, Level 3 certified, Electrical reliability

service related FAQ’s

All of our inspections are conducted in line with internationally recognised standards including ISO 18434 (condition monitoring using thermography) and IEC 62446-3 (thermographic inspection of PV and electrical systems). Our reports are also compliant with BS 7671 (IET Wiring Regulations), making them fully accepted by insurers and facilities managers.

Most insurers mandate annual thermal imaging inspections because electrical faults such as loose connections, phase imbalance, and overloads can lead to fire or equipment failure. Thermography provides a non-intrusive, live-testing method that detects these issues early. By submitting a certified thermographic report, businesses demonstrate proactive risk management, reducing liability and ensuring compliance with insurer requirements.

Our certified reports include high-resolution thermal images of each distribution board, annotated findings, and categorised risk levels (from minor to critical). Each issue is documented with clear explanations and recommendations. This report not only satisfies insurance compliance but also supports your planned preventative maintenance strategy.

The time required depends on the number of distribution boards, sub-panels, and switchgear on site. A small business may only require a few hours, while larger facilities with multiple panels can take a full day or more. We provide clear scheduling in advance to minimise disruption and ensure full coverage of your systems.

No. Thermographic inspections are carried out live, under normal operating loads, to ensure accuracy. Panels are opened by a qualified electrician, and our Level 3 Certified Thermographers conduct the imaging safely without interrupting your business operations. This makes the process both efficient and non-disruptive.

service related FAQ’s

Any business with commercial-scale electrical systems can benefit from thermography. This includes offices, warehouses, factories, retail units, and industrial facilities. Whether you operate a single site or a nationwide network, annual thermographic inspections provide a vital layer of risk reduction, compliance, and operational assurance.

Insurers typically require an annual inspection for compliance purposes, but some high-risk or heavily loaded systems may benefit from more frequent surveys. Annual thermographic inspections provide a balance between cost and risk management, ensuring that developing faults are caught before they become critical.

A Level 3 Thermographer brings the highest level of training and certification available in thermography. This ensures correct interpretation of anomalies, professional documentation, and reports that are recognised by insurers, auditors, and regulatory bodies. Using a lower-level operator risks misinterpretation, which could invalidate insurance compliance.

While not guaranteed, many insurers look favourably on businesses that carry out annual thermography inspections. By demonstrating proactive risk management and providing certified reports, businesses may benefit from reduced premiums, improved renewal terms, or simplified claims processes in the event of an incident.

Yes. We offer tailored pricing for businesses operating across multiple sites or with large numbers of distribution boards. Volume pricing makes it more cost-effective to roll out thermographic inspections at scale while ensuring each site receives the same Level 3 certified quality of service. Contact us for a customised quotation based on your portfolio size.