IEC 62446-3:2017 Compliant Solar Panel Thermal Imaging Inspections

Certified PV Solar Inspections for Optimal Performance & Safety

Ensure Your Solar System Meets IEC 62446 Standards with Expert Thermal Imaging Surveys & Electrical Inspections

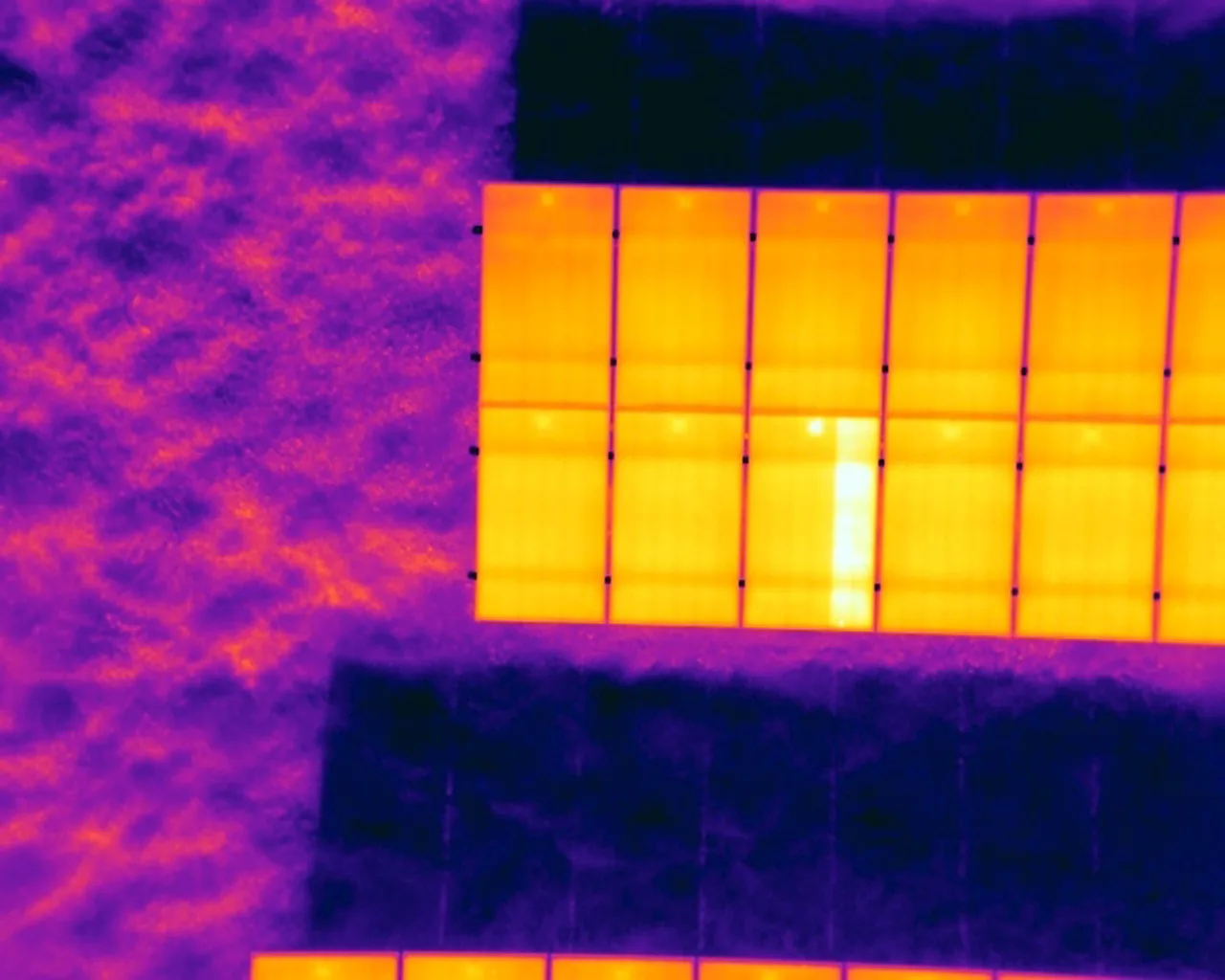

We provide certified solar panel inspections using high-resolution drone and ground-based thermal imaging, fully compliant with IEC 62446-3:2017. Our process identifies critical faults such as module hotspots, defective cells, bypass diode issues, and thermal mismatch — all without disruption to your system.

All inspections follow our structured Survey → Analysis → Reporting methodology, delivering clear, standards-aligned reports suitable for asset managers, O&M providers, EPC contractors, and insurers.

To complement thermal findings, we offer optional string-level electrical testing in line with IEC 62446-1:2016 and IEC 61829, including non-invasive checks of voltage, current, insulation resistance, and I-V curve performance — giving you a complete view of your system’s health.

At Thermography Services UK, we provide IEC 62446-3:2017 compliant thermal inspections for residential, commercial, and industrial solar PV systems. Using advanced infrared thermography and conducted by certified Level 3 Master Thermographers, we identify faults early to help prevent failures, optimise performance, and support long-term reliability.

Where required, we also offer string-level electrical testing in accordance with IEC 62446-1:2016, allowing for deeper analysis of system health and electrical performance. All services follow our structured Survey → Analysis → Reporting approach, and reports are formatted to meet the needs of insurance, warranty, and maintenance professionals — giving you clear, actionable insights without disruption to your system.

Schedule Your Solar PV Inspection Early – Book Now!

Ensure your solar PV system is efficient, safe, and fully IEC compliant.

Book early to avoid peak-season delays. Our certified Level 3 Thermographers deliver accurate, insurance-approved reports — with optional string-level electrical testing available for deeper performance insight. Trusted by homeowners, businesses, and asset managers across the UK.

Understanding IEC 62446-3:2017 / 62446-1 and Why It Matters

Understanding the IEC 62446-3:2017 Standard

IEC 62446-3:2017 formalises the methodology for conducting solar panel thermal imaging inspections, ensuring they are performed under controlled conditions with consistent processes, qualified personnel, and compliant equipment. This prevents false readings and misdiagnosed faults, providing reliable data to support system maintenance and performance optimisation.

Key Principles of IEC 62446-3:2017

Standardised Inspection Methodology: Inspections must follow a repeatable process — aligning with best practices for thermographic surveys under the Survey → Analysis → Reporting framework.

Controlled Environmental Conditions: Thermal imaging must be performed in clear, stable sunlight with limited wind interference and temperature differentials sufficient to reveal thermal anomalies.

Certified Thermographers & Equipment: The standard requires high-resolution infrared cameras (≥640×480) and inspections carried out by certified personnel — such as our Level 3 Master Thermographers.

Structured, Compliant Reporting: Reports must include geotagged thermal imagery, anomaly classifications, and recommended next steps — formatted in accordance with IEC guidelines.

Optional Electrical Testing Under IEC 62446-1

For systems requiring deeper diagnostics, we also offer string-level electrical testing performed in accordance with IEC 62446-1:2016 and IEC 61829. This complements thermal findings with data such as voltage, current, insulation resistance, and I-V curve behaviour — adding valuable context for performance assessment or fault correlation.

By working to these international standards, Thermography Services UK delivers reliable, independent inspection data that supports compliance, protects warranties, and helps ensure your solar PV system performs at its best.

Why Choose Thermography Services (UK) Ltd for Your Solar PV Inspection?

When it comes to ensuring the efficiency, safety, and compliance of your solar PV system, choosing the right thermography provider is essential. At Thermography Services (UK) Ltd, we specialise in IEC 62446-3:2017 compliant solar inspections, providing highly accurate thermal imaging assessments for homeowners and businesses.

When it comes to ensuring the efficiency, safety, and compliance of your solar PV system, choosing the right thermography provider is essential. At Thermography Services (UK) Ltd, we specialise in IEC 62446-3:2017 compliant solar inspections, providing highly accurate thermal imaging assessments for homeowners and businesses.

By choosing Thermography Services (UK) Ltd, you benefit from expert knowledge, industry-compliant reporting, and advanced inspection techniques, helping you maximise your solar investment and maintain peak system performance. Book your solar PV thermal inspection today!

Schedule Your Solar PV Inspection Early – Book Now!

Ensure your solar system is efficient, safe, and IEC 62446-3:2017 compliant. Avoid peak-season delays by scheduling your thermal inspection early this year. Our certified Level 3 Thermographers provide accurate, insurance-approved reports for homeowners and businesses.

Ensuring the efficiency, safety, and compliance of your solar PV system is essential for maximising energy output and preventing costly failures. The IEC 62446-3:2017 standard sets the benchmark for thermal imaging inspections, ensuring that all assessments are conducted under optimal environmental conditions using certified thermographers and high-quality infrared equipment.

At Thermography Services (UK) Ltd, we offer comprehensive, IEC-compliant thermal imaging inspections for homeowners and businesses, detecting hotspots, bypass diode failures, string mismatches, and Potential Induced Degradation (PID) before they impact performance or become a safety hazard. Using drone-mounted and handheld infrared cameras, our surveys are non-invasive, highly accurate, and insurance-approved.

Our fixed-price inspections provide clear, detailed reports that support warranty claims, insurance applications, and ongoing maintenance planning. With solar systems requiring regular maintenance to prevent power loss and fire risks, booking an IEC-compliant inspection early in the year ensures that any necessary repairs or adjustments can be made before peak energy demand periods.

📅 Book your IEC 62446-3:2017 solar PV inspection today and safeguard your solar investment!

FAQ’s

It’s recommended during annual maintenance checks, performance reviews, post-installation validation, or when thermal anomalies are suspected to have an electrical cause. It is especially valuable for system benchmarking, fault correlation, or prior to warranty expiry.

PID is a gradual performance degradation in solar panels caused by voltage leakage within the system. It leads to electrical losses and reduced efficiency. Thermal imaging detects PID by identifying uneven temperature gradients across the panel surface, indicating areas where electrons are migrating incorrectly, causing energy loss and long-term system failure.

For accurate results, the IEC 62446-3:2017 standard requires:

- Clear sunny sky conditions with at least 600W/m² of solar irradiance.

- Minimal wind speeds to avoid heat dissipation from convection cooling and affecting thermal readings.

- No Rain, Moisture, Dew, Snow, Mist to avoid heat dissipation from convection cooling and affecting thermal readings.

These conditions ensure precise thermal imaging and prevent false readings due to environmental interference.

Thermal imaging identifies hotspots, cracked cells, faulty bypass diodes, delamination, water ingress, loose electrical connections, and Potential Induced Degradation (PID). These issues can reduce energy output, increase fire risks, and lead to expensive repairs if left unaddressed. Early detection helps homeowners and businesses optimise performance and prevent costly failures.

String-level testing measures the electrical performance of PV strings — including voltage, current, insulation resistance, and polarity. It helps detect hidden faults such as underperforming strings, diode issues, or insulation degradation that may not be visible in thermal imagery.

Yes. Shading and dirt accumulation cause temperature variations across the panel surface, reducing overall performance. Thermal imaging can highlight areas of underperformance, allowing homeowners to take corrective actions such as cleaning, repositioning, or replacing affected panels to restore maximum energy generation.

No — all electrical testing is performed non-invasively from ground level using industry-grade instruments. We do not access internal inverter components or climb onto the roof. This ensures safety and minimal disruption during inspection.

Industry recommendations suggest annual solar panel inspections, particularly for commercial installations and high-performance systems. According to UK government guidelines, regular maintenance, including thermal imaging assessments, helps extend the lifespan of PV systems and maintain peak efficiency. Some manufacturers require inspections every 1-2 years to maintain warranty coverage.

IEC 62446-1:2016 is the international standard that defines the required electrical tests, documentation, and reporting for verifying the performance and safety of grid-connected photovoltaic (PV) systems. It is most commonly applied during commissioning, routine maintenance, or fault investigations — ensuring that the electrical characteristics of a solar installation meet design expectations and operational safety requirements.

As part of our optional string-level electrical testing service, we carry out non-invasive tests in accordance with IEC 62446-1 to assess the DC-side health of your solar system. These tests include:

- Open-Circuit Voltage (Voc) – Verifies correct string voltage and helps detect module or connection faults.

- Short-Circuit Current (Isc) – Confirms expected current output under standard irradiance.

- Insulation Resistance – Checks the electrical insulation of PV strings relative to ground to identify degraded cables or potential safety risks.

- Polarity Verification – Ensures correct string wiring and identifies reverse connections.

- String Continuity – Confirms uninterrupted connectivity through the string.

These electrical tests are typically performed from accessible locations such as DC isolators or inverter string terminals, no roof access or system disassembly is required. When combined with thermal imaging inspections under IEC 62446-3, this provides a comprehensive picture of both electrical and thermal performance, all delivered through our structured Survey → Analysis → Reporting methodology.

The results are compiled into a clear, standards-aligned report designed for your installer, O&M provider, or insurer to interpret and act on.

Yes, an IEC 62446-3:2017 compliant thermal inspection provides documented proof of faults such as hotspots, cracked cells, or manufacturing defects. Many solar panel warranties require thermal imaging evidence to support claims, allowing homeowners to secure free repairs or replacements from manufacturers.